Recommended

by

Building Inspectors Nationwide

What is High Lift and Low Lift Grouting? |

|||||||||||||||||||||||||||||||||

High

Lift and Low Lift grouting are terms used in building codes

to define the method of placing grout in reinforced masonry

walls. Codes allow the contractor to choose either method

unless the structural engineer requires one or the other.

Low Lift grouting may or may not require the use of inspection

or clean-out openings. High Lift grouting will require inspection

openings spaced no more than 32 inches apart or at each rebar

location. |

|||||||||||||||||||||||||||||||||

Advantages

of High Lift Grouting |

|||||||||||||||||||||||||||||||||

Smart Masonry Systems has recognized the value of the High Lift grouting method as referenced in ACI 530. Mason Contractors can easily choose the High Lift grout method to increase block production and project efficiency. The following demonstrates the obvious cost advantages of choosing the High Lift grout method over Low Lift grouting:

|

Commonly

Asked Questions |

No. Smart "T-Bolts" are designed to wedge against the inner shell face of a block opening from 1 inch to 4-1/2 inches wide. The Smart "T-Bolt" can be rotated any degree to accommodate a narrower shell width. We recommend that you order inspection block from your block manufacturer or saw cut your inspection openings. Hammer cutting block is not recommended since it produces block fatigue, produces excessive debris and wastes block units. Do you need special tools for the Smart Masonry Clean-Out System? No. The Smart "Nut" is designed to be hand tightened. What if the specifications restrict grouting to the low lift method? Many engineers feel that the use of plywood and other non-transparent covers can lead to unfilled or unconsolidated grout cells. Submit the Smart Masonry Clean-Out System to the Engineer and chances are you will be able to switch to High Lift grouting. What about Tooled finished walls? Many contractors hide the clean-out opening behind bottom of wall base boards. Building codes allow a minimum clean-out opening of 3 inches by 3 inches. |

Installation |

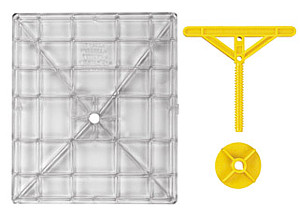

Pre-assemble the Smart Masonry Clean-Out System as shown in this picture. Hold the threaded end of the "T-Bolt" with one hand. Insert

the "T" part of the "T-Bolt" vertically

through the clean-out opening of the block.

Hand tighten the "Nut" with your other hand and the Smart Masonry Clean-Out System is now installed. |

Brochure

Introduction |

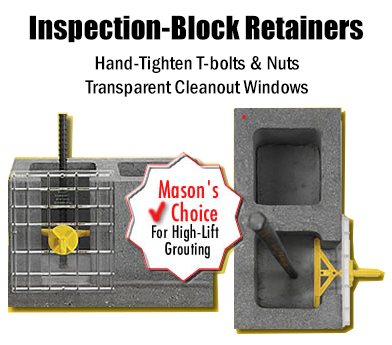

The Smart Masonry Clean-Out System is a revolutionary system used to form Clean-Out Covers for High Lift grouting. It consists of a "T-Bolt," a re-usable "Nut" and a re-usable transparent "Window." The "T-Bolt" and "Nut" are made from hard ABS plastic. The transparent "Window" clean-out cover is made of poly carbonate, an extremely durable material commonly used in jet fighter canopies. While the "Nut" and Window" are re-usable, the exposed portion of the "T-Bolt" easily breaks off after removal of the "Nut" and "WIndow" to provide a fast, clean, professional and economical means of forming reinforced masonry clean-out covers.

Smart Transparent Window, T-Bolt & Nut |

Benefits |

||

Causes no damageto the face of the block and requires no patching of block as with the plywood/nailing method of forming clean-out covers. Eliminates costly blow-outs that require chiseling and grinding. Adds to your professional image. The Smart Masonry Clean-Out System, when installed, demonstrates the professionalism expected by engineers, architects, general contractors and especially inspectors. Plywood and hammer cut inspection holes lead to excessive waste and cleanup.

Quick Installation - can be installed and removed in seconds, vastly reducing labor costs. Corrosion

Resistant - made from strong ABS plastic

instead of metal, removing concern for corrosion of exposed

fasteners.

|

|

|

Toll-Free

Phone: (800) 525-4744 |

www.masonrystore.com Welcome/Order | Brochure | Distributors | Policies | Testimonials | Contact

Us |

Does

The Smart Masonry Clean-Out System require precision block

openings or cell widths?

Does

The Smart Masonry Clean-Out System require precision block

openings or cell widths? It

takes a

few seconds!

It

takes a

few seconds!

Advanced

Placement - allows for inspection through

the transparent "Window" and readiness to pour

immediately after inspection. No need for hammers, nails,

plywood and bruised thumbs.

Advanced

Placement - allows for inspection through

the transparent "Window" and readiness to pour

immediately after inspection. No need for hammers, nails,

plywood and bruised thumbs.